100% Original Electronic Auto Glass Film - high quality laminated pdlc film – Noyark Detail:

DESCRIPTION

Noyark high quality laminated pdlc film is ideal for glass lamination.

We have produced our standard non-adhesive smart film for lamination for nearly 15 years. The non-adhesive smart film is used mainly for the manufacture of laminated smart glass.

Over the years there have been a number of improvements made to the liquid crystal and the latest generation of film offers excellent performance, consistency, clarity and longevity.

Noyark has already supplied several of the world’s largest glass laminators. If your company is looking to produce your own smart glass, please contact us for more information about becoming an OEM Partner.

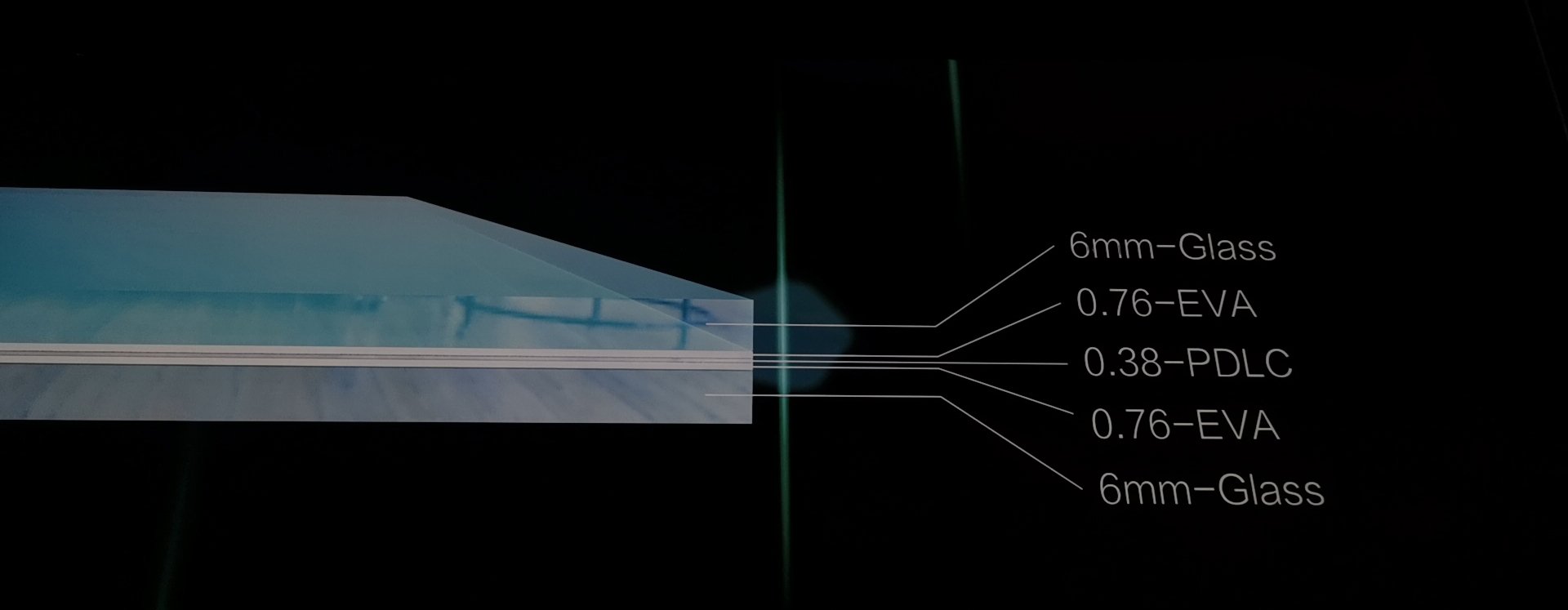

The film is laminated using either PVB or EVA (bagging method) with a standard autoclave.

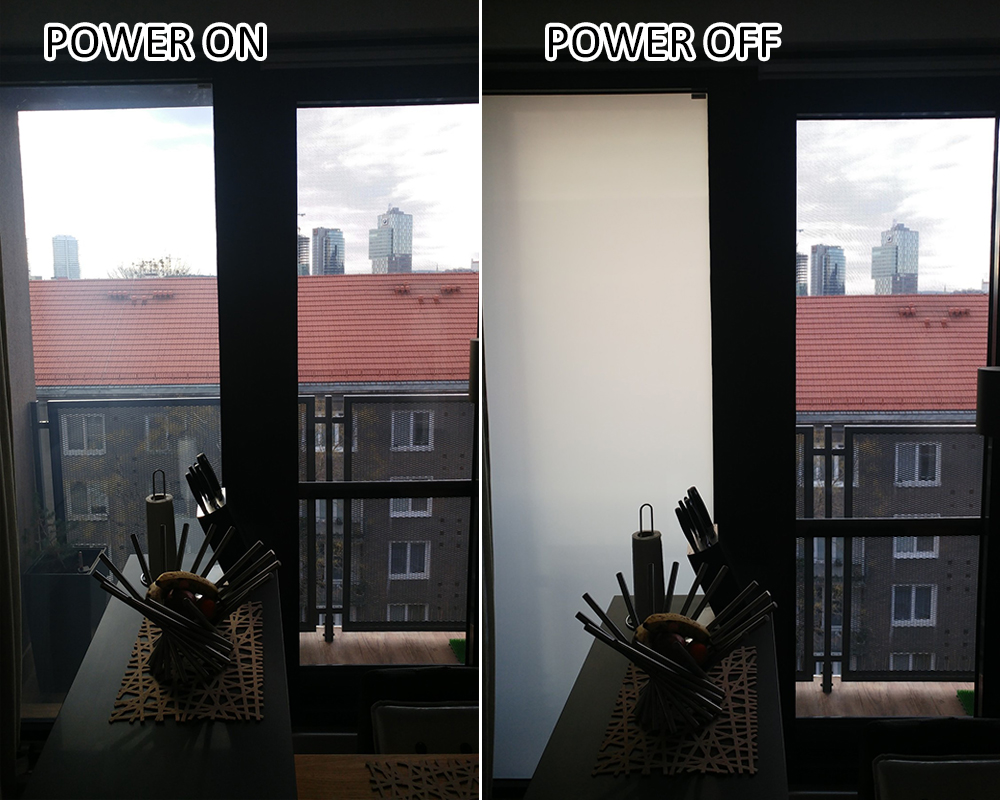

This unique technology will also transform any glass into a high definition rear projection screen to display corporate presentations, TV images and videos.

High quality laminated pdlc film is available in 4 standard widths 1000mm, 1200mm, 1500mm, 1800mm and 2000mm with a maximum sheet length of 3660mm (recommended), which can be cut to any size or shape.

FEATURES

+ Autoclave lamination (PVB/EVA).

+ Customizable sizes and shapes.

+ Multiple Color Options: white, black, gray, blue, red, yellow, etc.

+ Multiple Control Mode: remote control, wall switch control, WIFI control, APP control, sound control, light control, etc.

BENEFITS

SPECIFICATIONS

WHY CHOOSE US

1. Hi-Tech Manufacturing Equipment

Our core manufacturing equipment is imported directly from Germany.

2. Strong R&D Strength

We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.

3. Strict Quality Control

3.1 Core Raw Material.

Our ITO film (no shrinkage, no color difference) and liquid crystal spacer (excellent uniformity) are imported directly from Japan; glue is imported directly from Europe; our liquid crystal temperature range is 70°C and protective film is resist to high temperature 80-90°C.

3.2 Finished Products Testing.

High & low temperature test at 75°C and -35°C for 500 hours; thermal shock test 10°C-90°C for 30 minutes; damp heat test for 500 hours; moisture removed by oven; smart films in sheet are powered by a 24-hour aging test; smart films in roll are tested with 100V high voltage to make sure zero breakdown.

4. OEM & ODM Acceptable

Customized sizes and shapes are available. We have automatic cutting machine, manual cutting machine and laser cutting machine.

FACTORY TOUR

Product detail pictures:

Related Product Guide:

Smart Glass Market by Technology, End-Use Industry | Smart Film Pdlc

EU data protection regulation: what you need to know | Switchable Film Switchable Glass

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for 100% Original Electronic Auto Glass Film - high quality laminated pdlc film – Noyark, The product will supply to all over the world, such as: Netherlands , Melbourne , Algeria , we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!